Design and Development of Ultra-High-Precision Manufacturing Technologies

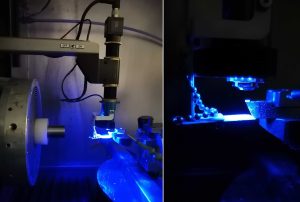

Ultra-precision machining is the recent realm subsequent to conventional precision machining processes. Recently, achieving nanoscale features on products has become important in manufacturing of critical components. Through further development of computer numerical controlled machinery technology, single-point diamond turning (SPDT) has evolved rapidly and became a key step in the process chain of nano-machining. In SPDT, advanced and competitive technology for optical surface generation combined with ultra-precision fixtures and accurate metrological systems, high-precision surface machining with scales down to 1 nanometer, even less than 1 nanometer, are successfully achieved

Advanced Manufacturing Technologies

Design and Development of Medical Devices and Surgical Techniques

cutting-edge technology solutions seamlessly intertwine the essence of human interaction with the technology and digital health

Biomedical Engineering

Design and Development of Sensors and High-Precision Metrology Solutions

cutting-edge technology solutions seamlessly intertwine the essence of human interaction with the technology and digital health

Sensors and Metrology systems

Designed for forward-thinking marketing agencies, this template encapsulates a blend of sleek design elements and dynamic animations.

Advanced Control Systems

Automatic Control Systems

CNC Machines and

3D Printing Technologies

Research Associate at

Nelson Mandela University

0{{current_slide_index}} | 0{{total_slide_count}}

Dr. Shahrokh Hatefi is currently a Post-Doctoral Researcher at Nelson Mandela University. He has a Ph.D. and a Post-Doctorate in Mechatronics Engineering. He recently attained a Y2 NRF rating. He has over 7 years of experience as an academic lecturer in different universities. He has been collaborating with different research groups and scientific organizations for many years.

He produced 8 invention patents and published over 30 peer-reviewed scientific articles in peer-reviewed journals.

Recent collaborations with universities, scientific organizations, and private sector

Academic Background and Activities

Mechatronics Engineering

Post-Doctorate in Mechatronics Engineering, Ph.D. in Mechatronics Engineering, Masters in Mechatronics Engineering.

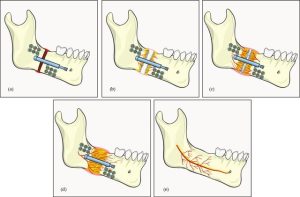

Biomedical Engineering

8 invention patents and more than 10 research projects on design and development of medical devices and surgical techniques.

Advanced Manufacturing

More than 6 years of experience in advanced Manufacturing technologies and hybrid manufacturing methods. Design and development of hybrid ultra-high-precision single-point diamond turning technologies.

Control Systems

More than 15 years of experience in the field of Electrical Engineering and Control Systems. More than 6 years of experience as an academic lecturer in different international universities, in the field of electrical and control engineering.

Peer Review

Reviewed over 100 scientific articles for different Elsevier, MDPI, Springer, SAGE, and Frontiers journals.

Editorial Roles

Guest Editor in Applied Sciences, MDPI. Review Editor of the Frontiers of Mechanical Engineering journal.

Prof. Javad Alizargar

Assistant Professor, National Taipei University of Nursing and Health Sciences

I have known Dr. Hetefi for many years through our collaboration in manufacturing, design, patent applications, and brainstorming in the biomedical field. His talent and dedication are exceptional. As a leader in biology, he can guide projects to success with his visionary insights. Our collaboration has resulted in over four patent registrations and ten scientific journal publications.

Dr. A Navaei

PDG, SIEN France Company

The project "production of the medical-grade face masks" was done in collaboration with Dr. Hatefi during the COVID-19 pandemic, which I am very satisfied with. Great responsibility, high expertise, and professional service are his bold characteristics, which were clearly evident in my experience with him. Thank him for his hard work, and we will definitely collaborate with him on the next projects.